Contaminated water can be purified for drinking using just three empty plastic bottles thanks to new research by Nottingham Trent University.

Contaminated water can be purified for drinking using just three empty plastic bottles thanks to new research by Nottingham Trent University.

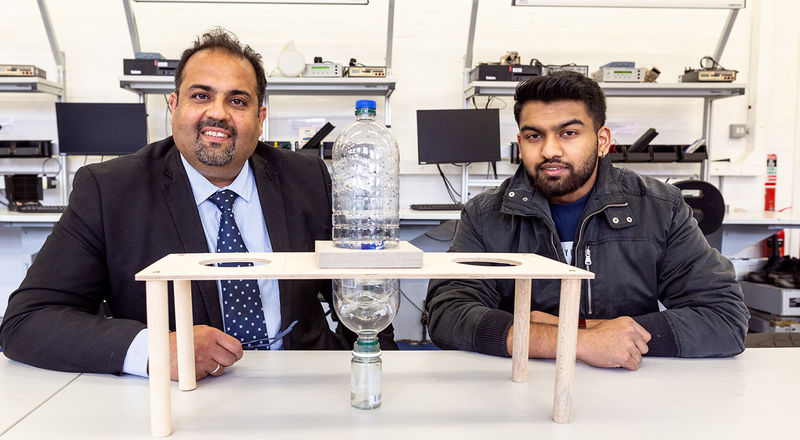

A project led by Professor Amin Al-Habaibeh – an expert in intelligent engineering systems - will allow people in developing countries to clean dirty water and seawater in a sustainable way.

The technology centres on harnessing sunlight to warm natural water. As the water warms the clean evaporation is captured in a chamber and stored safely, ready to be consumed.

Just 1,000 of the purifiers – spanning an area of only 25 metres squared - would be enough to produce a pint of pure water a day. They can be made with everyday throwaway plastic bottles such as cola bottles.

Professor Al-Habaibeh, of the School of Architecture, Design and the Built Environment, said: “This simple technology which utilises ordinary discarded plastic bottles will allow people in developing countries to farm their own clean water.

“By cutting the bottles in a certain way, and putting them together with resin, people would be able to create clean drinking water, albeit in small amounts.

“But by scaling up the number of these water purifiers, it would be possible for people without access to clean drinking water to sustain themselves.

“The only real materials needed are those which are thrown away, making the project cost-free. It’s a way to utilise thrown-away plastic bottles to help sustainability.”

The creation of one of the purifiers requires two plastic bottles to be cut in half, with the two top halves of these bottles being stuck together, end to end, with a screwcap lid at either end. This makes the chamber. The bottom cap is removed and the chamber is then stood in the bottom half of one of these bottles.

The bottom half of a smaller bottle is inserted inside the chamber and placed on a stand made from remaining plastic. This smaller bottle is filled with dirty water which evaporates into the top of the chamber and then condenses, becoming water again and passing down the sides of the chamber.

The clean water is then collected in the base and stored separately to the dirty water, making it safe to consume.

The research team will develop instructions in different languages which will enable people in developing countries to make the water purifiers themselves.

Final year BSc Product Design student Clemens Devarajan, who worked on the idea for his final year design project, said: “We are not claiming any intellectual property for the design. We would like to provide this information freely so that people can copy it and create their own clean water.

“The aim of this project is to help people in developing countries. If you had thousands of these purifiers all connected you could create enough water for a small family and to clean our environment from unneeded plastic bottles.”

A project led by Professor Amin Al-Habaibeh – an expert in intelligent engineering systems - will allow people in developing countries to clean dirty water and seawater in a sustainable way.

The technology centres on harnessing sunlight to warm natural water. As the water warms the clean evaporation is captured in a chamber and stored safely, ready to be consumed.

Just 1,000 of the purifiers – spanning an area of only 25 metres squared - would be enough to produce a pint of pure water a day. They can be made with everyday throwaway plastic bottles such as cola bottles.

Professor Al-Habaibeh, of the School of Architecture, Design and the Built Environment, said: “This simple technology which utilises ordinary discarded plastic bottles will allow people in developing countries to farm their own clean water.

“By cutting the bottles in a certain way, and putting them together with resin, people would be able to create clean drinking water, albeit in small amounts.

“But by scaling up the number of these water purifiers, it would be possible for people without access to clean drinking water to sustain themselves.

“The only real materials needed are those which are thrown away, making the project cost-free. It’s a way to utilise thrown-away plastic bottles to help sustainability.”

The creation of one of the purifiers requires two plastic bottles to be cut in half, with the two top halves of these bottles being stuck together, end to end, with a screwcap lid at either end. This makes the chamber. The bottom cap is removed and the chamber is then stood in the bottom half of one of these bottles.

The bottom half of a smaller bottle is inserted inside the chamber and placed on a stand made from remaining plastic. This smaller bottle is filled with dirty water which evaporates into the top of the chamber and then condenses, becoming water again and passing down the sides of the chamber.

The clean water is then collected in the base and stored separately to the dirty water, making it safe to consume.

The research team will develop instructions in different languages which will enable people in developing countries to make the water purifiers themselves.

Final year BSc Product Design student Clemens Devarajan, who worked on the idea for his final year design project, said: “We are not claiming any intellectual property for the design. We would like to provide this information freely so that people can copy it and create their own clean water.

“The aim of this project is to help people in developing countries. If you had thousands of these purifiers all connected you could create enough water for a small family and to clean our environment from unneeded plastic bottles.”